Custom orders: MAGNET tailors its services to bring Cleveland builders to market

Cleveland’s Manufacturing Growth Advocacy Network (MAGNET) tailors its consulting services around the demands of Northeast Ohio’s builder marketplace. As not all manufacturing needs are created equal, the organization assists entrepreneurs all the way from early-stage prototyping to bringing products to market.

Andrea Navratil, director of new ventures for MAGNETAdditionally, the flexibility of MAGNET’s operations is reflected in the organization’s annual Mspire pitch competition—Ohio's only pitch challenge exclusively for manufacturing-focused entrepreneurs—notes Andrea Navratil, director of new ventures for the manufacturing group. MAGNET is constantly adapting its sales, technical support and business strategy offerings for winning participants.

Andrea Navratil, director of new ventures for MAGNETAdditionally, the flexibility of MAGNET’s operations is reflected in the organization’s annual Mspire pitch competition—Ohio's only pitch challenge exclusively for manufacturing-focused entrepreneurs—notes Andrea Navratil, director of new ventures for the manufacturing group. MAGNET is constantly adapting its sales, technical support and business strategy offerings for winning participants.

“We’ve grown alongside our entrepreneurs to offer the services they need to scale up and get to market,” says Navratil. “We have people doing pilots and need that minimally viable product. Or they’re already at market and need help in messaging and identifying their value.”

MAGNET held its seventh annual Mspire competition this summer, with customized awards encompassing marketing assistance and guidance around lean operations vital to getting manufacturers’ products off the ground.

This year’s contest also expanded into northwest Ohio via a sponsorship from ProMedica Innovations—a Toledo early-stage venture capital firm. Winners included a medical device company and a designer of flame-resistant clothing for women working in motorsports and industrial occupations.

MAGNET operates within a value proposition framework, aiding entrepreneurial charges in communicating the benefits of their product or service. An early-stage startup requires engineering design services around initial product development. A more established company like competition winner Skuld, meanwhile, may be ready to display their foundry innovations to potential customers.

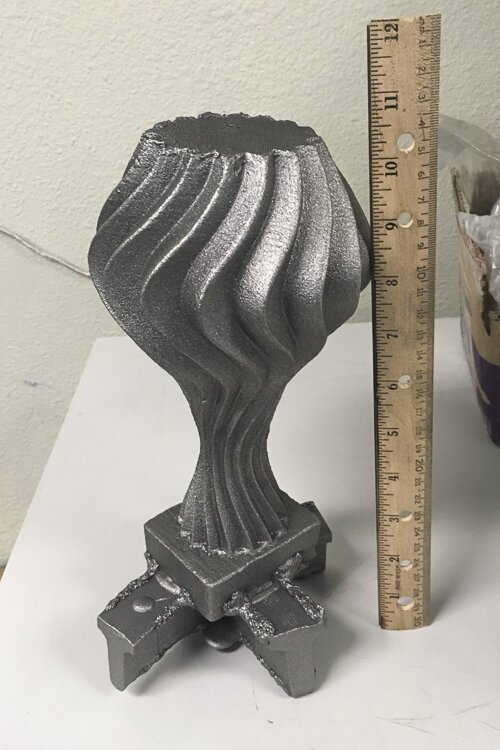

Skuld won its MSPIRE award for a hybrid manufacturing process that merges 3D printing with lost-foam casting to create complex metal pieces.In Skuld’s case, MAGNET is providing booth space and marketing materials for the Manufacturing and Technology Show in Cleveland this October. A trade show booth will put Skuld in front of players in defense and other areas where their products are best served.

Skuld won its MSPIRE award for a hybrid manufacturing process that merges 3D printing with lost-foam casting to create complex metal pieces.In Skuld’s case, MAGNET is providing booth space and marketing materials for the Manufacturing and Technology Show in Cleveland this October. A trade show booth will put Skuld in front of players in defense and other areas where their products are best served.

“Skuld has identified that manufacturers need faster, less expensive tooling early on, so that’s the messaging they need to show off,” says Navratil. “This is an opportunity to let them think through their operations as they grow.”

Putting a face to a name

Skuld CEO Sarah Jordan is excited to show off her technology to would-be users at the upcoming trade show. Based in Springfield, Ohio, the company won its MSPIRE award for a hybrid manufacturing process that merges 3D printing with lost-foam casting to create complex metal pieces.

The environmentally friendly method starts with a polystyrene mold material which can then be cast into products for the defense, aerospace and automotive industries. Jordan, a metallurgical engineer who began developing the innovation with co-founder Mark DeBruin in 2015, says the process is faster and more efficient than alternatives like additive manufacturing.

“You can use that type of manufacturing for complex shapes, but it’s costly and takes a long time,” says Jordan. “We can make large metal parts in under 12 hours, and the cost is comparable to traditional manufacturing instead of having ten times the markup.”

Bringing well-made parts to market “at Amazon speeds” will be Jordan’s elevator pitch at the October trade event, she says. MAGNET’s booth prize was appealing for the simple benefit of its visibility.

Skuld CEO Sarah Jordan“It’s good anytime I can get our technology in front of potential users,” says Jordan. “They can’t buy from us if they don’t know we exist. It’s an opportunity to talk about our work and potential applications around the technology and will let us refine what we’re doing based on that feedback.”

Skuld CEO Sarah Jordan“It’s good anytime I can get our technology in front of potential users,” says Jordan. “They can’t buy from us if they don’t know we exist. It’s an opportunity to talk about our work and potential applications around the technology and will let us refine what we’re doing based on that feedback.”

Jordan and DeBruin are also polishing their marketing message with a hand from MAGNET. Partnering with a knowledgeable organization serves as a force multiplier for two career engineers who admittedly lack marketing experience. That doesn’t even include the design and engineering support folded into the Mspire package.

“We’ve been trying to do that marketing ourselves, but you can tell if that’s professionally done, or put together by an engineer,” says Jordan. “We want things to look professional because that’s going to be people’s first impression.”

Navratil of MAGNET says Skuld has been “wonderful” to work with. The organization will continue to buoy nascent businesses currently dealing with supply chain and workforce challenges. Ideally, that bridge building will sustain Northeast Ohio’s manufacturing economy.

“I’m in this space because I believe innovation is where all industry needs to grow,” Navratil says. “It’s very straightforward to me.”