The cool kids do it: From fish food to electronics, manufacturing offers unique jobs aplenty

For people thinking that manufacturing is just about “building stuff”—as has been the story around the industry for untold decades—that designation is far from accurate.

Sure, you could rely on the North American Industry Classification System, which says a business belongs in the manufacturing realm if it’s “engaged in the mechanical, physical, or chemical transformation of materials, substances or components into new products.”

Furthermore, “this work is most likely to take place in a plant, factory or mill using power-driven machines and materials-handling equipment.”

However, any establishment that makes new products can be included in this sector—from tailors to bakers to electronic equipment manufacturers. Michael O’Donnell, vice president of operations for Cleveland’s

Manufacturing Growth Advocacy Network (MAGNET), says it’s imperative for the industry to better showcase the numerous unique and interesting job pathways available.“How can we get the word out that manufacturing is cool?” says O’Donnell. “People are coming into the workforce with inaccurate perceptions. But they’ve never been in a factory, so how would they know?”

Eating good in the neighborhood

Eating good in the neighborhood

Job seekers would be wise to get a slice of the food production pie, which incorporates manufacturing, processing, R&D, and agriculture. And the marketplace is not limited to food consumed by humans—the animal food production industry uses processed raw ingredients to yield feed for livestock and household pets.

Downstream demand from both pet owners and farm supply owners help support the industry, even as revenue has declined in recent years due to weakness in the red meat, corn, and wheat markets.

What about our ocean-going friends, then? O’Donnell says there is growing fish feed market estimated to be worth $170 billion by 2026. Fish feed is generally segmented into corn, soybean, fish oil, fishmeal, and additives. Painesville-based OmegaSea is elevating its game by using Alaskan herring and salmon in place of fishmeal. These ingredients are processed and packaged on site, using a hot steamroller-like apparatus that dries the fish for flaking.

Technology is a mainstay of the modern food processing sector. Bettcher Industries, known globally for its line of meat shearing and trimming equipment, is just one example of how meat disassembly needs skilled talent to fulfill rising demand in consumption.

Meanwhile, gas systems are increasingly being used for poultry slaughtering, requiring automated procedures overseen by trained operators. Meat inspectors are taught to find blood spots or tumors on meat in an environment that is cleaner with better lighting than what the general public may expect.

“The whole thing is highly mechanized,” says O’Donnell. “Most people may not think that.”

Milk pasteurization— the process of killing bacteria in milk on the journey from cow to carton—is itself an exceedingly technical undertaking that follows strict government regulations. In most milk processing plants, chilled raw milk is heated by passing it between stainless steel plates until it reaches optimum temperature.

The industry also uses centrifuges that separate milk into cream and skimmed milk, with buttermilk created by churning cream at high speeds in a large vat. Butter is forced through perforated plates to disperse moisture and work the contents into a more solid consistency. All these processes require capable labor to make them happen.

“Even farmers have new milking machines that are automated,” says O’Donnell. “You need a skilled person who can maintain this equipment.”

‘Manufacturing is cool’

Modern manufacturing is experiencing wholesale change as innovations such as artificial intelligence, robotics, and the Internet of Things (IoT) transform the workplace.

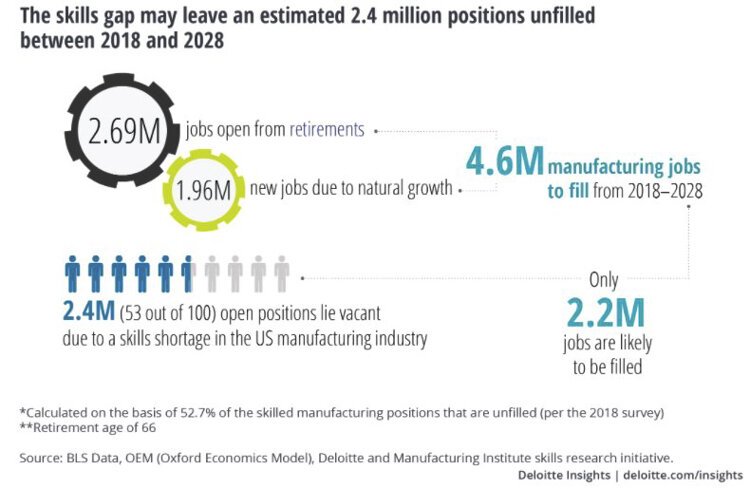

Though more jobs are being created, a 2018 study from Deloitte cited a skills gap that may leave an estimated 2.4 million positions unfilled by 2028.

O’Donnell points to lighting as just one area with endless potential applications. Fiber optics and acrylic technologies are combined to backlight computer keyboards or various items, including baby blankets.

“Keyboards have LEDs and a sheet of acrylic that’s scored to let the light out,” explains O’Donnell. “People are needed to build these things.”

Locally, Kent Displays makes liquid crystal films for its Boogie Board electronic writing surface. Users can write on the display – much like a normal sheet of paper—and erase the surface with the touch of a button.

Hair-thin carbon fibers are yet another innovation spun into various inventions, among them deicing technologies for jet fighter windshields.Teams of engineers and skilled workers are needed now to produce these advances—it’s up to companies and industry advocates like MAGNET to let the world know these jobs exist, O’Donnell remarks.

SME supports Manufacturing Day which helps foster learning and collaboration between manufacturing companies and young creators.Sector partnerships can connect manufacturers to would-be workers who have misconceptions around the industry. Every October, National Manufacturing Day addresses those harmful “dirty, dark, and dangerous” stereotypes by opening facility doors and displaying what manufacturing is—and what it isn’t.

SME supports Manufacturing Day which helps foster learning and collaboration between manufacturing companies and young creators.Sector partnerships can connect manufacturers to would-be workers who have misconceptions around the industry. Every October, National Manufacturing Day addresses those harmful “dirty, dark, and dangerous” stereotypes by opening facility doors and displaying what manufacturing is—and what it isn’t.

Amplifying the voices of individual manufacturers should be a year-round effort, one that reaches not only high schoolers, but younger students as well, industry advocates say. For instance, when O’Donnell’s son attended Avon Lake Middle School a decade ago, he helped build a six-foot-tall medieval trebuchet in math class. Eager students engineered the device to fling projectiles as far as they could go—a fun, but educational introduction to manufacturing.

These same young learners may not be building siege weapons as a career, but simply letting them know the possibilities in manufacturing provides potential for an exciting future.

“Catch those kids as early as possible,” says O’Donnell. “It’s a one-on-one battle to get that information out there. Manufacturing is cool, and it’s necessary because we can’t live without it. People can make a difference if they get into the industry.