Manufacturing Alliance ‘in this together’ for PPE sourcing and creation

Tips for manufacturers trying to navigate the coronavirus crisis

What are practical solutions for manufacturers struggling during the coronavirus? MAGNET has answers for companies trying figure out their next steps:

*Cash is king: For companies that already leveraged their line of credit, consider the Small Business Administration’s low-interest disaster relief loans, which can be used to pay fixed debts, payroll, accounts payable and other bills.

*Stay covered: Consult your attorney and insurance broker to determine coverage for business interruptions. Though a complex topic spanning multiple forms of insurance, having this discussion now can protect you from virus-related impacts.

*Legal aid: Labor and employment laws are changing in a COVID-19 world. Fact sheets from the Department of Labor answer questions on employee paid leave rights and more.

*An open line: Keep full transparency with customers on key aspects of your COVID-19 preparation and response, even if it costs you money in the short term.

*Keep it clean: Follow proper procedures for disinfecting your manufacturing facilities, whether it’s locker rooms, machine control panels, time clocks, or other surfaces. The EPA has a list of disinfectants for use against SARS-CoV-2.“In This Together Ohio” is Gov. Mike DeWine’s mantra against COVID-19—a battle cry that calls upon every resident to take part in getting the state through the coronavirus pandemic.

Togetherness in the face of adversity has trickled down to Ohio’s manufacturing sector, in the form of a coalition sourcing Personal Protective Equipment (PPE) to help healthcare workers treat patients safely. The newly-formed Ohio Manufacturing Alliance brings together an army of Ohio makers creating everything from face shields to cloth masks to nasal swabs for COVID-19 testing.

Cleveland’sManufacturing Advocacy and Growth Network (MAGNET) and the Ohio Manufacturers’ Association formed the group in late March and joined forces with the Ohio Hospital Association, Ohio Manufacturing Extension Program (MEP), JobsOhioand a selection of nursing homes.

MAGNET plays a key role in the public-private partnership by connecting suppliers and by providing engineering support. Almost 2,000 companies have answered a summons from alliance supporter DeWine to repurpose their operations and produce PPE for front-line medical workers.

Much like the way Goodyear in Akron made fighter planes during World War II, the alliance gathers local manufacturers in a different kind of fight—the fight against COVID-19—notes MAGNET president and CEO Ethan Karp.

Splash shield by Ohio Emergency PPE Makers ExchangeThe alliance helps manufacturers determine needed equipment and how to adapt current products and operations to meet demand. In early April, the group assembled a team of Ohio manufacturers to make up to one million face shields over a five-week span.

Splash shield by Ohio Emergency PPE Makers ExchangeThe alliance helps manufacturers determine needed equipment and how to adapt current products and operations to meet demand. In early April, the group assembled a team of Ohio manufacturers to make up to one million face shields over a five-week span.

MAGNET coordinated the effort by linking suppliers and engineers. Case Western Reserve University, power management company Eaton, and MAGNET engineers designed and built the shield prototype.

Karp says the project is emblematic of what the initiative can accomplish moving forward, as the face shields will be shipped from Hudson-based Little Tikes—a manufacturer that normally builds plastic toys.

Little Tikes is assembling the shields from material supplied by other companies, with the alliance quickly organizing the larger supply chain.

“This type of production usually takes seven months, but we wanted it in five weeks,” says Karp. “The face shield was an inspiration for the alliance and showed we could do this. Without the alliance, we couldn’t have pulled the companies together to make it happen.”

Beyond PPE

Tapping into a deep industrial base has resulted in more than just face masks, alliance leaders maintain.

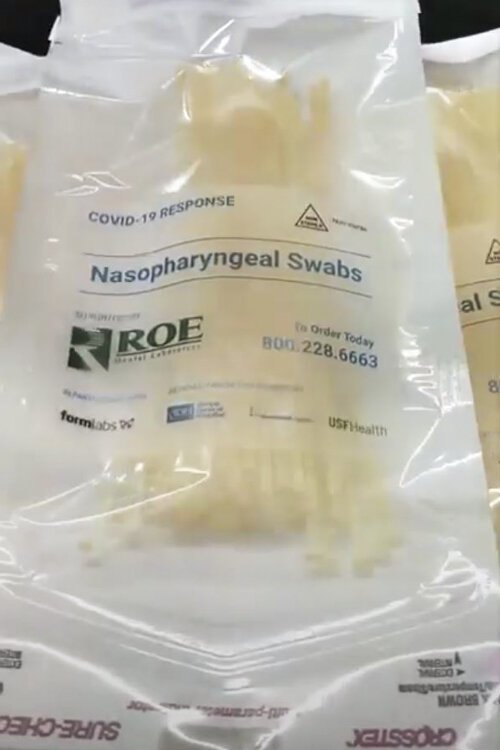

Cleveland Whiskeyis collaborating with Cleveland Clinic to formulate and bottle hand sanitizer for the health system. Meanwhile, ROE Dental Laboratory in Independence is 3D printing nasal swabs for testing the coronavirus. Though orders for ROE’s facial reconstruction materials has fallen off, the swabs represent a potential new market sector where test kit components are in high demand.

Each organization in the alliance is knocking down barriers to PPE. Ohio MEP, with MAGNET in the lead, provides engineering capabilities and technical support.The manufacturing group manage manufacturer outreach, while the hospital group and partner nursing homes offer insight on the most needed PPE products. Rounding out the mix is JobsOhio, which delivers financial assistance to help accelerate production.

“I’ve never seen anything like this collaboration,” Karp says. “From the Governor on down, we’re saying if we can’t buy something, this is how we’re going to make it. Everyone’s volunteering to make a difference in this space.”

Navigating issues around the face shield is a prime example of the alliance’s efficacy, adds Karp. Three area hospitals tested and clinically approved the shield prototype] , with private-sector businesses and economic development agencies fast-tracking hard-to-find plastic.

MAGNET secured emergency funding through JobsOhio to procure materials, aided by a team of die cutters, injection molders and assemblers to generate effective face mask molds.

“When we saw we weren’t getting enough plastic, we had Eaton use its supply chain,” says Karp. “Then we went to our network of die cutters to find plastic, and two companies had sizable amounts they locked up for us. Redundancy in the system allowed us to fix what was broken. There's no sole sourcing of anything."

Karp says this process can serve as model for future PPE creation, including isolation gowns and cotton masks.

ROE Dental Laboratory in Independence is 3D printing nasal swabs for testing the coronavirus.“We can marry what manufacturers say they can do to viable alternative products,” he says. “We’ve learned about the ingenuity and tremendous willingness to do what is right from most of our manufacturers. There’s been an unbelievable response.”

ROE Dental Laboratory in Independence is 3D printing nasal swabs for testing the coronavirus.“We can marry what manufacturers say they can do to viable alternative products,” he says. “We’ve learned about the ingenuity and tremendous willingness to do what is right from most of our manufacturers. There’s been an unbelievable response.”

Companies with ideas for retooling products can fill out a survey on the alliance website,. Karp expects new needs will arise even as the pandemic is brought under control.

Although the face shield shortage issue is resolved for now, plastic partitions separating grocery store customers from clerks may be non-medical essentials in the near future.

In late April, the alliance launched the Ohio Emergency PPE Makers Exchange, an online marketplace where organizations that require PPE and related equipment can find a wide selection offered by Ohio manufacturers.

“I have no idea if this is going to be a permanent alliance,” says Karp. “What I hope is more people appreciate made-in-Ohio and made-in-the-U.S.A. products, and we keep the spirit of collaboration borne between manufacturers and all these organizations. ‘In It Together Ohio’ is the governor’s hashtag. Let’s take that momentum so a year from now we can fix workforce challenges that are perennially an issue.”